COMPOSITES (PEEK)

Replacement of bearing bushes and wear rings in bronze, metal, PTFE or rubber for pumps.

Humitab can offer you the following wear-resistant composites composed of PEEK and carbon fibre:

- CF30 ( 70% PEEK + 30% carbon fibre ) - Tube - Radial bearing

- CW70 ( 30% PEEK + 70% carbon fibre ) - Tube - Radial bearing

- CP50 ( 50% PEEK + 50 % carbon fibre ) - Plate - Axial bearing

- Pure PEEK - Tube - Rod

- Graphite Filled PEEK - Tube - Rod

Advantages

Less electricity consumption

Less vibrations

Possibility to decrease the gap between impellar-pumphousing and bushing-sleeve

Less maintenance and downtime costs

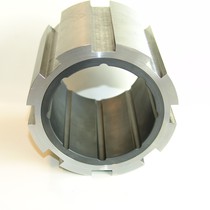

CF30

CF30 is a temperature and pressure moulded composite consisting of 70% PEEK and 30% carbon fibre. It is the perfect bearing material for vertical pumps and for wear rings on impellers.

Advantages

CW70

CW70 is a wound tube material consisting of 30% PEEK and 70% carbon fibre. This combination results in an exceptionally strong material with superior qualities.

Advantages

CP50

CP50 is a material with wound carbon fibres that are compressed together with PEEK into plates by means of an autoclave.

Advantages

Diverse PEEK Composites

For specific applications we can offer a broad range of composites.

Nederlands

Nederlands Français

Français English

English